Folosire:

Submersible axial mixing and aerating equipment has been designed to aerate activated basins of biological waste water treatment plants, or as the case may be the ponds, etc. Should there be any request for activation with nitrification and denitrification, the equipment may at the same time perform the function of time-separated function of stirring only with no aeration made.

|

|

|

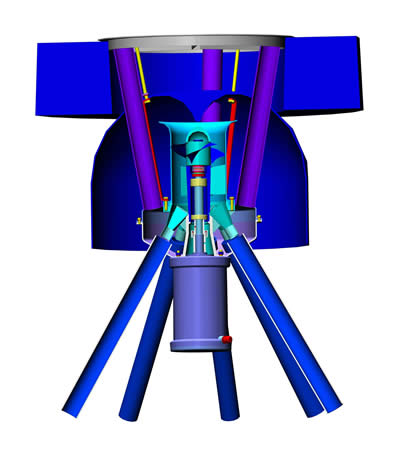

Descrierea functiei: Submersible electric motor drives the impeller that pumps over

a great amount of liquid while using dynamic effect of flowing liquid

that provides for induction of large quantity of air,its mixing,splitting

to fine bubbles followed by displacement of mixture of water and

fine air bubbles into the aerating volume. |

Stainless components to the hydraulic part:

Datele tehnice:

Currently only the powers of 1,1 – 2,2 – 4,0 – 7,5 kW magnitudes are manufactured. Now a major demand from abroad has been put forward to supply more pieces of equipment with 30 to 40 kW. Upon development of this equipment we did not assume to manufacture that big equipment more powerful than given in the Table. Therefore at present we are engaged in preparing design change (simplification) of this mechanical equipment in order to be able to supply those with substantially higher powers.During year 2003 numerous measurements within specific municipal l and industrial waste water treatment plants were conducted under various operating conditions having a significant impact on actual – operational oxygenation capacity:

- Water and air temperatures

- Sludge concentration and liquid viscosity

- Above-sea level (altitude)

- Water height in activation

- Oxygen concentration in activation and oxygen demand rate

- It has been found out the alpha coefficient may - depending on particular WWTP - move within the range of 0,5 to 0,9

Therefore, the actual and operating yields under various conditions

move within the ranges as mentioned in the Table.

Consequently, it is only our Company that makes PAM equipment design of

aerating a specific WWTP. The design will be developed based on the results

of these extensive measurements carried out within specific WWTPs.

Due to these measurements we assume the actual electric power consumption

during aeration of activation is at least 20% lower compared to fine-bubble

aeration systems used in Czech Republic. This even under unfavourable

conditions for PAMP equipment.

PAM equipment features a rather interesting fact that with increasing

slurry concentration the air bubbles’ diameter gets reduced thus increasing

oxygen introduction.Therefore the PAMP equipment seems to be an ideal

tool for separated aerobic stabilization of excessive sludge where oxygen

yields (recoveries) are higher than the figures given in the Table.

Concerning less concentrated effluents and activation with aerobic stabilization

of excess sludge the oxygenation capacity of PAMP equipment is higher

than its stirring capability. Therefore, it is required that PAMP equipment

is designed in terms of its agitating ability as well.

PAMP equipment leads to the floating device and the reason is to ensure

maximal aeration performance even in case there is fluctuation of water

level inside activation tank(activated sludge basin). You must anchor

the equipment to a chosen spot using the ropes attached over the basin’s

circumference. If required, these ropes may serve to move the equipment

to the basin’s wall.Portable swing crane is used either to remove it from

inside or fit it in the basin.

| Type |

Installed capacity N |

Power take-off P |

Oxygen operating yield |

Agitation max. depth |

Max. agitated diameter |

Dimension L |

Dimension D |

Mass |

| (kW) |

(kW) |

(kg/kWh) |

(m) |

(m) |

(mm) |

(mm) |

(kg) |

|

| PAMP-0,55 | 0,55 |

0,4 |

1,5-2,5 |

2,5 |

2,5 |

700 |

800 |

20 |

| PAMP-1,1 | 1,1 |

0,9 |

2,0-3,0 |

3,0 |

3,5 |

930 |

1100 |

40 |

| PAMP-2,2 | 2,2 |

1,9 |

2,0-3,0 |

3,5 |

7 |

930 |

1100 |

80 |

| PAMP-4,0 | 4,0 |

3,5 |

2,0-3,0 |

4,5 |

11 |

1500 |

1300 |

120 |

| PAMP-7,5 | 7,5 |

6,5 |

2,0-3,0 |

5,0 |

15 |

1500 |

1300 |

160 |

| PAMP-11 | 11 |

- |

2,0-3,0 |

5,0 |

- |

- |

- |

- |

| PAMP-18 | 18 |

- |

2,0-3,0 |

5,0 |

- |

- |

- |

- |

Equipment of 0,55 x 11 x 18 dimensions have not been manufactured yet,

thus the Table shows only the assumed parameters able to be derived from

the equipment manufactured so far.

Maximal agitating capacity will be under such conditions the equipment

is placed inside the basin with water depth equal to that stated in this

Table.

With smaller water depth the maximal agitated diameter lowers by double or triple the difference between maximal agitated depth”(mentioned in this Table) and the actual water depth.For example when you consider fitting PAMP-4 equipment in the basin with 3,5 m water depth, then the actual maximal stirring diameter of this equipment will get reduced in the following way 11 (4,5 3,5) . 2,5 = 8,5 m.In order to increase stirring efficiency we recommend to implement those adaptations within the basin bottom as illustrated by the following

The design:

ALVEST PROX, s.r.o. will carry out calculations and designing of the equipment.

Example:

It is required to design aeration system for activation WWTP for 5000

EO.

Accurate calculation of oxygen demand is feasible, however the aeration

equipment has to be designed to cover the peaks. Therefore, various authors

advise the aeration equipment performance to be rated as multiple 2,5

to 3,5 times BOD5 in kg/day. Concerning our example the operational OC

= (5000 . 0,06) . 2,5 = 750 kg O2/day = 31,25 kg O2/hour.

When usage of equipment of PAMP-4 magnitude is considered having operating

yield under optimal conditions of at least 4 kg O2/kWh, then their required

number will be n = (OC/4)/P = (31,25/4)/3,5 = 2,23 pcs.

The suggestion is 3 pcs of PAMP-4 with operation control (ON / OFF) run

by EGO sensor (exhaust gas oxygen sensor).

Ilustration of the function after switching ON the equipment.

Termene:

Oferta in decurs de 3 zile. Livrarea si montajul depinde de marimea instalatiei si diapazonul livrarii, minimum 2 luni.

Garantii si servicii:

Waranty for the equipment is 24 months. Services concerning xR and SR equipment malfunctions will be carried out through replacement method, i.e.- within 12 hours from reporting the failure a spare PAMP equipment shall be delivered to secure WWTP operations up until returning the original equipment repaired.

Advantages of the equipment:

The advantages of this equipment designed for aeration of municipal and other biological treatment units are as follows:- Minimal demands in terms of maintenance. The unit does not contain any mechanical gears that would impair energy transfer and in particular increase the failure and damage hazards.

- Easy and quick to install.

- Minimal noise level - the equipment is submerged completely under water surface.

- Electric power consumption concerning more powerful PAMPs of first generation is roughly 20-30 % lower than with fine bubble aeration systems.

- One single equipment is capable to aerate and agitate simultaneously

the activation contents to ensure nitrification and denitrification

in one basin - it is recommended with smaller-size treatment units

up to ca 5 000 EO. - Simple and cheap control system for electric power consumption - only through frequent switching ON and OFF of the running equipment - recommended for treatment units up to 10 000 EO.

- For most of the treatment plants we recommend to combine PAMP equipment with highly effective agitators along with only the PAMP equipment being switched ON and OFF intermittently.

- When activation mixture passes via the axial impeller the fibrous microorganisms get cut thus substantially limiting fibre sludge bulking - i.e. sludge index lowers and sludge separation characteristics improve.

- The entire equipment is very simple, requiring no construction site for location of pressure air supplies and hence lowering your building costs. When arranged appropriately this treatment unit is capable to reduce your costs rather significantly, especially those incurred to building part - refer to item 2 of this Catalogue.

- Lower investment costs spent on technology when compared to fine-bubble aeration systems.

- Longterm life even when treating chemically agressive effluent water (only stainless materials and fibreglass are applied), where fine-bubble systems are subject to extreme heavy duty stresses and their life gets lowered substantilly.

- When finebubble aeration system is involved, then due to its material construction the ageing and wear of aeration membrane is eminent and will happen relatively very quickly followed by oxygen transfer efficiency being lowered gradually with subsequent rise of electric power consumption. When mechanical aerator PAMP (stainless steel and fibreglass only) is concerned one can expect substantially higher service life (at least two times) compared to finebubble systems due to structure simplicity and material version applied.

- High oxygenation capacity even with shallow basins - significantly higher than with finebubble systems (mixing the air and liquid inside mixing tube at high speed followed by the mixture flowing to the activation basin bottom corresponds to substantilly higher pressure rations and not to the actual geodetic depth of placing under the water level).

- Ideal aerating and mixing equipment for SBR reactor - the least expensive technological arrangement of biological waste water treatment plant possible.

- When operating more WWTPs this PAMP may serve as mobile facility

as well in case of emergency when aeration at some of the treatment

units breaks down.

Cross-section of PAMP equipment

|

|

Placing PAMP equipment inside basin

.