Folosire:

Submersible axial agitator is used for homogenization, agitation and circulation of liquids within effluent water treatment plants, in industry and civil engineering. Agitators are suitable for smaller basins and those of rectangular plan. |

dă un clic pentru mărire |

|

Function Outline:

The equipment makes use of streamline flow effect to ensure stirring, and for this purpose vane impellers have been developed to impart strong axial flow to the liquid together with balance (uniform) speed alongside the entire vane of the impeller.Datele tehnice:

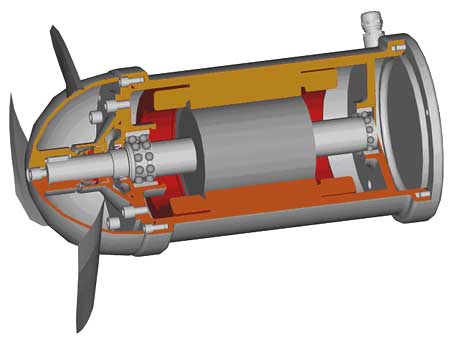

Submersible agitator MX consists of electric motor, gland, impeller and support bracket (carrier). Fitted together to form one unit this assembly makes MX agitator a simple compact set that surpasses conventional stirrers as far as investment costs and operating reliability are concerned. Vane impeller comprises its hub and two atypical impeller blades with the hydraulic parameters set up in an optimal way. The vane impeller has been installed right on the rotor of submersible electric motor. It has been manufactured using precision casting process in material version 17460.Submersible motor-induction squirrel-cage with 4-pole winding. Motor jacket (housing,shell) as well as its covers (lids) are made through precision casting process in material version 17460. To cool the motor its heat will be transferred from motor jacket to the surrounding liquid.

Shaft sealing. One external mechanical seal with face seal in combination with the inner seal complete with oil charge. It is installed on the gland.

Carrier (support)bracket.It consists of two clamping clips (sleves), the carrier and anchoring plates. Use clamping sleeves to fasten the agitator to the carrier bracket.The carrier bracket has a mounting lug of 20 mm hole diameter used to install a handling cord (cable) - the chain. Anchoring plate is used to fix the agitator during its installation inside the basin. For the ways anchoring is made refer to the following

Performance Parameters:

| Magnitude | Output Installed |

Power Input Take-Off |

Energy Availability |

Basin Max. Volume |

Max. Size B * L |

Mass |

(kW) |

(kW) |

(W*m-3) |

(m3) |

(m) |

(kg) |

|

| MX 1,1 | 1,1 |

0,9 |

12 |

75 |

3 x 6,25 |

35 |

| MX 1,5 | 1,5 |

1,3 |

12 |

108 |

3 x 9 |

37 |

| MX 3,0 | 3,0 |

2,7 |

10 |

270 |

4 x16 |

52 |

| MX 7,5 | 7,5 |

7,1 |

9 |

800 |

10 x 20 |

92 |

Agitator Scheme (Download: AutoCAD_01):

Legenda:

1 Motor housing

2 Stator of electrick motor

3 Rotor of electric motor

4 Impeller

5 Mechanical Seal

6 Gland

7 Guffero

8 Upper Bearing

9 Lower Bearing

10 Carrier Bracket

Building and Anchoring Dimensions:

| TYPE | Fixing Dimensions |

Building Dimensions |

|||

D1 mm |

A mm |

B mm |

D mm |

L mm |

|

| MX 1,1 | 9 |

40 |

200 |

200 |

344 |

| MX 1,5 | 9 |

40 |

200 |

235 |

344 |

| MX 3,0 | 11 |

60 |

220 |

280 |

388 |

| MX 7,5 | 17 |

100 |

350 |

350 |

600 |

Delivery Specification:

The delivery comprises MX agitator complete with carrier bracket and electric cable 10m long. Apply a separate order for additional supply of the leading (guidance) bracket, starting device and the probe to monitor any ingress of liquid into the gland. The leading bracket and the starting device are made of material version steel 17241.Termene:

Offer put forward within 1 day. Delivery within two to six weeks.

Garanții și servicii

Warranty for the equipment is 24 months.

Guarantee service within two days, after-guarantee service within two

weeks following a receipt of failure notice.

Avantajele:

- Simple structure;

- Low price;

- Individual construction elements are manufactured using precision

casting process in material version 17460;

- Maximal agitating performance ensured due to directing the streamline

flow properly thanks to agitator loosely anchored to the leading bracket;

- Material version provides for long life even when liquids with little contents of abrasive material are used.

Examples of Applications: